Our Engineers |

|

|

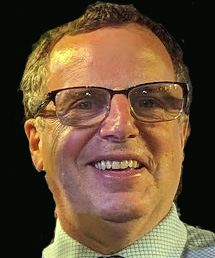

Dan Leeser, President of Innovative Material Technologies, has over 40 years of experience in materials and program management.

After graduating from the University of Delaware (Newark, DE) with a degree in Chemical Engineering, Dan started his career at General Dynamics (now Lockheed Martin Aeronautics) in Fort Worth, TX working in composite production support for the F-16 fighter and then taking a substantial role in developing the thermoplastic technologies for the company. Dan moved on to ICI Fiberite (Winona, MN and Tempe, AZ), one of the worlds leaders in thermoset and thermopastic prepreg manufacturer. Dan's initial focus was with thermoplastic composite tape materials and qualifying these materials to aerospace specifications. Dan traveled throughout the US and Europe promoting thermoplastic composites and supplying technical support. Dan then lead a team of technical service and process engineers focused on developing new products, improving manufacturing processes and working with customers to specify and qualify materials. The next step in Dan's career brought him to Quadrax, Inc (Portsmouth, RI). Quadrax had just purchased thermoplastic prepreg equipment from Phillips Petroleum. Quadrax was transitioning from primarily making parts for the defense industry such as thermoplastic composite panels for the Seawolf submarine into non-defense products focusing on sporting goods including golf club shafts, putter heads, tennis racquets, bicycle parts, lacrosse sticks and hockey sticks. Dan was part of the team that helped develop the materials and the processes to produce these parts. Dan's career then switched to adhesives. First he worked for ITW Plexus (Danvers, MA) that made methacrylate adhesives for the marine and automotive industries. Dan's role at Plexus included technical service, testing, product development and program management. Dan was part of a team that developed and patented a new innovative toughened acrylic adhesive. Then he moved to Emerson and Cummings (Burlington, MA) where he was the Technical Manager for a start-up division tasked to provide film epoxy adhesives for unique applications. Dan's trajectory shifted one more time as he then went to Aspen Aerogels (Marlborough, MA) where he worked on aerogel insulations. These unique aerogel products were used in clothing, deep-sea oil pipelines, automotives and several other industries. As Aspen was a small growing company, Dan got experience in all aspects of the business incuding manufacturing, customer support and product development. Dan was involved in developing several patentable materials and concepts: Composites Based on Macro and Nanoporous Materials, Energy Efficient and Insulated Building Envelopes, Light Weight Insulation for Pipelines, Flexible Compression Resistant and Highly Insulating Systems, Coated Insulation Articles and Their Manufacture But Dan soon got drawn back into the composite world working at Triton Sytems mainly performing program management and manufacturing for Small Business Innovative Research (SBIR) grants where much of his work centered around vacuum assisted resin transfer molding (VaRTM) and long fiber thermoplastic injection molding. Dan also spent time with Albany Engineered Composites (Mansfield, MA and Rochester, NH) were he worked on several research programs including Z-pinning of composites and selection and development of resin transfer molding (RTM) resins. From there Dan went to Toray Advanced Composites (TenCate Advanced Composites at the time) in Morgan Hill, CA where he started as a field technical support engineer. Working from his home in Massachusetts Dan provided guidance on materials and part manufacture for both thermoset and thermoplastic composite materials. Dan then moved to a Technology Manager role supporting thermoplastic composites with the focus on qualifying materials to aerospace specifications and improving the product for easier adaptation into part making scenerios. Which brings us to present day where Dan has decided to use his background and knowledge to help companies understand the materials they are using and assist in project and program management. |